Stainless Steel Coil

201 Stainless Steel Coil/Strip

Grade:310S, 314, 309S, 304, 304L, 316L etc.

Brand :TISCO, LISCO, ZPSS, BAOSTEEL

Thickness:0.1mm – 15mm

Width:3mm – 2000mm

Length:500mm – 3000mm

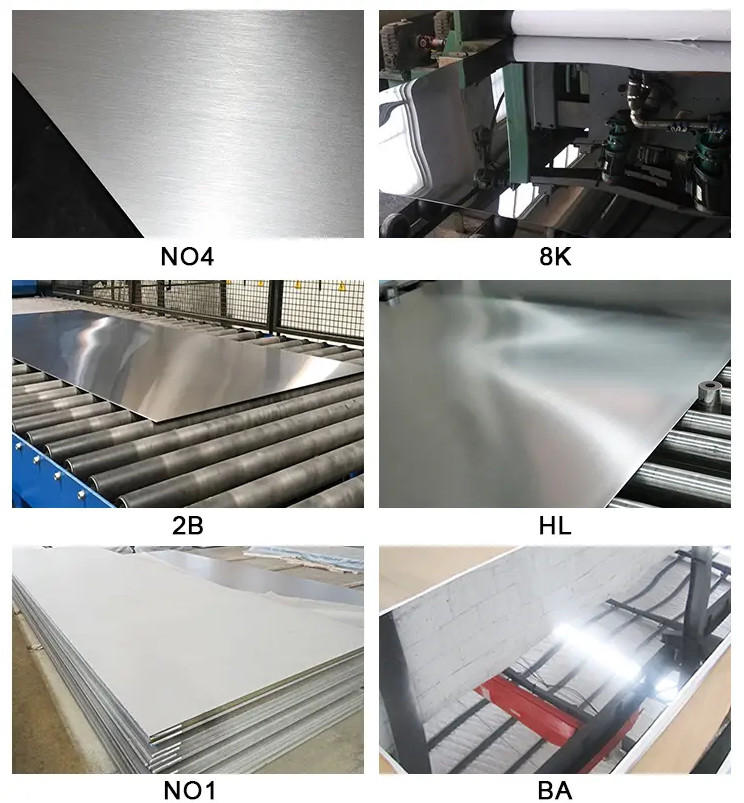

Surface: Polishing, Brushed, Annealed, etc.

Standard: AISI, ASTM, EN, BS, GB, DIN, JIS etc.

MOQ: 1 ton

| Item |

201 Stainless Steel Coil/Strip |

|---|---|

| Material |

310S,310,309,309S,316,316L,316Ti,317,317L,321,321H,347,347H,304,304L, 302,301,201,202,409,409L,410,410S,420,430,631,904L,Duplex,etc |

| Standard |

ASTM A240,GB/T3280-2007,JIS4304-2005,ASTM A167,EN10088-2-2005,etc |

| Surface |

2B,2D,BA,NO.1,NO.4,NO.8,8K,mirror,checkered,embossed,hair line,sand blast,Brush,etching,etc |

| Width |

3mm-2000mm or as required |

| Technique |

Hot rolled / cold rolled |

| Shipment time |

Within 7-10 working days after receiving deposit or L/C |

| Package |

Waterproof paper, and steel strip packed. |

| Capacity |

250,000 tons/year |

Product Chemical Properties:

|

Chemical Properties of Frequently-used Stainless Steel Material Grade |

|||||||||||

|

UNS |

ASTM |

EN |

JIS |

C% |

Mn% |

P% |

S% |

Si% |

Cr% |

Ni% |

Mo% |

|

S20100 |

201 |

1.4372 |

SUS201 |

≤0.15 |

5.5-7.5 |

≤0.06 |

≤0.03 |

≤1.00 |

16.0-18.0 |

3.5-5.5 |

- |

|

S20200 |

202 |

1.4373 |

SUS202 |

≤0.15 |

7.5-10.0 |

≤0.06 |

≤0.03 |

≤1.00 |

17.0-19.0 |

4.0-6.0 |

- |

|

S30100 |

301 |

1.4319 |

SUS301 |

≤0.15 |

≤2.00 |

≤0.045 |

≤0.03 |

≤1.00 |

16.0-18.0 |

6.0-8.0 |

- |

|

S30400 |

304 |

1.4301 |

SUS304 |

≤0.08 |

≤2.00 |

≤0.045 |

≤0.03 |

≤0.75 |

18.0-20.0 |

8.0-10.5 |

- |

|

S30403 |

304L |

1.4306 |

SUS304L |

≤0.03 |

≤2.00 |

≤0.045 |

≤0.03 |

≤0.75 |

18.0-20.0 |

8.0-12.0 |

- |

|

S30908 |

309S |

1.4833 |

SUS309S |

≤0.08 |

≤2.00 |

≤0.045 |

≤0.03 |

≤0.75 |

22.0-24.0 |

12.0-15.0 |

- |

|

S31008 |

310S |

1.4845 |

SUS310S |

≤0.08 |

≤2.00 |

≤0.045 |

≤0.03 |

≤1.50 |

24.0-26.0 |

19.0-22.0 |

- |

|

S31600 |

316 |

1.4401 |

SUS316 |

≤0.08 |

≤2.00 |

≤0.045 |

≤0.03 |

≤0.75 |

16.0-18.0 |

10.0-14.0 |

2.0-3.0 |

|

S31603 |

316L |

1.4404 |

SUS316L |

≤0.03 |

≤2.00 |

≤0.045 |

≤0.03 |

≤0.75 |

16.0-18.0 |

10.0-14.0 |

2.0-3.0 |

|

S31703 |

317L |

1.4438 |

SUS317L |

≤0.03 |

≤2.00 |

≤0.045 |

≤0.03 |

≤0.75 |

18.0-20.0 |

11.0-15.0 |

3.0-4.0 |

|

S32100 |

321 |

1.4541 |

SUS321 |

≤0.08 |

≤2.00 |

≤0.045 |

≤0.03 |

≤0.75 |

17.0-19.0 |

9.0-12.0 |

- |

|

S34700 |

347 |

1.4550 |

SUS347 |

≤0.08 |

≤2.00 |

≤0.045 |

≤0.03 |

≤0.75 |

17.0-19.0 |

9.0-13.0 |

- |

|

S40500 |

405 |

1.4002 |

SUS405 |

≤0.08 |

≤1.00 |

≤0.04 |

≤0.03 |

≤1.00 |

11.5-14.5 |

≤0.60 |

- |

|

S40900 |

409 |

1.4512 |

SUS409 |

≤0.08 |

≤1.00 |

≤0.045 |

≤0.03 |

≤1.00 |

10.5-11.75 |

≤0.50 |

- |

|

S43000 |

430 |

1.4016 |

SUS430 |

≤0.12 |

≤1.00 |

≤0.040 |

≤0.03 |

≤0.75 |

16.0-18.0 |

≤0.60 |

- |

|

S43400 |

434 |

1.4113 |

SUS434 |

≤0.12 |

≤1.00 |

≤0.040 |

≤0.03 |

≤1.00 |

16.0-18.0 |

- |

- |

|

S44400 |

444 |

1.4521 |

SUS444L |

≤0.025 |

≤1.00 |

≤0.045 |

≤0.03 |

≤1.00 |

17.5-19.5 |

≤1.00 |

- |

|

S40300 |

403 |

- |

SUS403 |

≤0.15 |

5.5-7.5 |

≤0.04 |

≤0.03 |

≤0.50 |

11.5-13.0 |

≤0.60 |

- |

|

S410000 |

410 |

1.40006 |

SUS410 |

≤0.15 |

≤1.00 |

≤0.035 |

≤0.03 |

≤1.00 |

11.5-13.5 |

≤0.60 |

≤1.00 |

|

S42000 |

420 |

1.4021 |

SUS420J1 |

0.16~0.25 |

≤1.00 |

≤0.04 |

≤0.03 |

≤1.00 |

12.0-14.0 |

≤0.75 |

≤1.00 |

|

S440A |

440A |

1.4028 |

SUS440A |

0.60~0.75 |

≤1.00 |

≤0.04 |

≤0.03 |

≤1.00 |

16.0-18.0 |

- |

≤0.75 |

|

S32750 |

SAD2507 |

1.4410 |

|

≤0.03 |

≤1.2 |

≤0.035 |

≤0.02 |

≤0.80 |

24.0-26.0 |

6.0-8.0 |

3.0-5.0 |

|

S31803 |

SAF2205 |

1.4462 |

|

≤0.03 |

≤2.0 |

≤0.03 |

≤0.02 |

≤1.00 |

21.0-23.0 |

4.0-6.5 |

2.5-3.5 |

|

N08904 |

904L |

1.4539 |

|

≤0.0.3 |

≤2.0 |

≤0.035 |

≤0.03 |

≤1.00 |

18.0-20.0 |

23.0-25.0 |

3.0-4.0 |

|

SURFACE |

DEFINITION |

APPLICATION |

|

NO.1 |

The surface finished by heat treatment and |

Chemical tank, pipe. |

|

2B |

Those finished, after cold rolling, by heat |

Medical equipment, Food industry, |

|

NO.3 |

Those finished by polishing with No.100 |

Kitchen utensils, Building construction. |

|

NO.4 |

Those finished by polishing with No.150 |

Kitchen utensils, Building construction, |

|

HL |

Those finished polishing so as to give |

Building Construction. |

|

BA (No.6) |

Those processed with bright heat treatment |

Kitchen utensils, Electric equipment, |

|

Mirror (No.8) |

Shinning like a mirror. |

Building construction. |

Q&A

Q:Are you trading company or manufacturer ?

A:We are professional manufacturer for stainless steel and our company also is a very professional and technical foreign trade company for stainless steel products.We have more export experience with competitive price and best after-sales service Apart from this we can provide a wide range of steel products to meet the requirement of customer

Q:Will you delivery the goods on time?

A:Yes,we promise to provide best quality products and delivery on time no matter if the price change lot or not.Honesty is our tenet.

Q:Do you provide samples ? Is it free or extra ?

A: The sample could can provide for customer with free,but the freight will be covered by customer account .The sample freight will be returned to customer account after we cooperate.

Q:Do you have any certifications?

A:Yes,that is what we guarantee to our clients. we have ISO9000,ISO9001 certificate,API5L PSL-1 CE certificates etc. Our products are of high quality and we have professional engineers and development team.

Q:What is your terms of payment ?

A:Payment<=1000USD,100% in advance. Payment>=1000USD,30% T/T in advance,balance before shipment or paid against copy of B/L within 5 working days.100% Irrevocable L/C at sight is favorable payment term as well

Q:Do you accept the third party inspection?

A:Yes absolutely we accept